Like-for-like replacement of a damaged cable or dislodged connector to restore a transducer back to full working order following its mis-handling.

REPAIR

We offer a swift and cost-effective but thorough load cell repair service so that your equipment can be restored to optimal performance with minimal downtime. We’re able to revive most load cells regardless of their manufacturer or capacity.

Home > Our Services > Repair

Our 4 step repair process

Fluid communication and total transparency is at the heart of everything we do. Our repair process has therefore evolved to include strict hold points – we shall not carry out any modifications to your device without your consent or knowledge of the potential costs involved moving forward.

Investigate & Diagnose

Visually:

Assess any physical damage or wear.

Electrically:

Check for connectivity or signal integrity issues.

Response:

Analyse behavior under load.

Report Findings

Our findings and recommended corrective actions are thoroughly documented, before being reported back to you.

Please note:

A repair can only be offered if all replacement parts are available, and the device has not been subjected to excessive physical overload. We also cannot correct electrical damage to instrumentation.

We shall not proceed from here without your consent.

Repair

If given permission to do so, we will act upon our recommendations with utmost care and precision to restore your device back to full working order.

Test

Finally, optimum performance will be ensured prior to dispatch through rigorous testing of your device. We’ll check all acquired data meets the device’s original specification before reporting our results back to you.

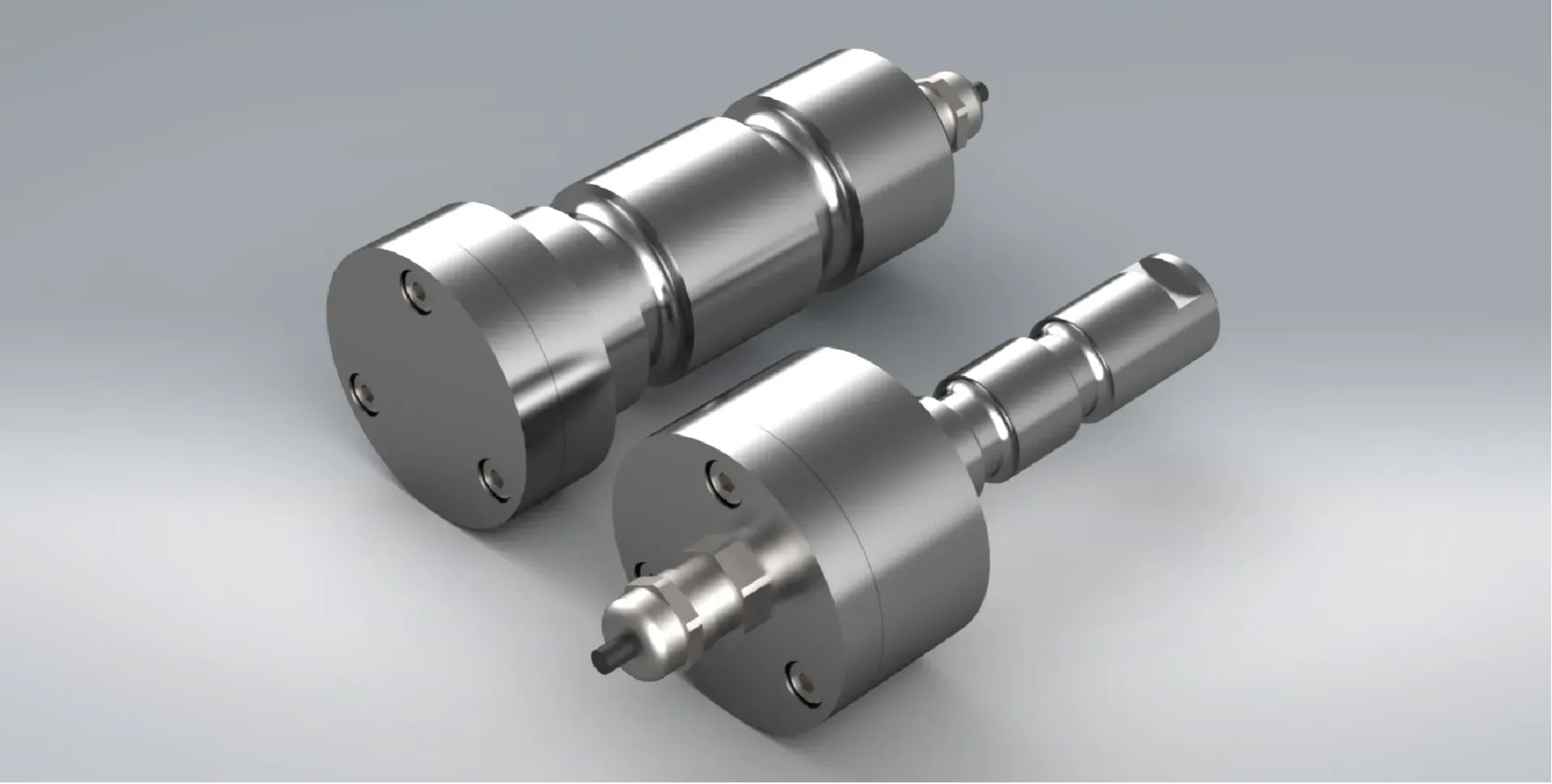

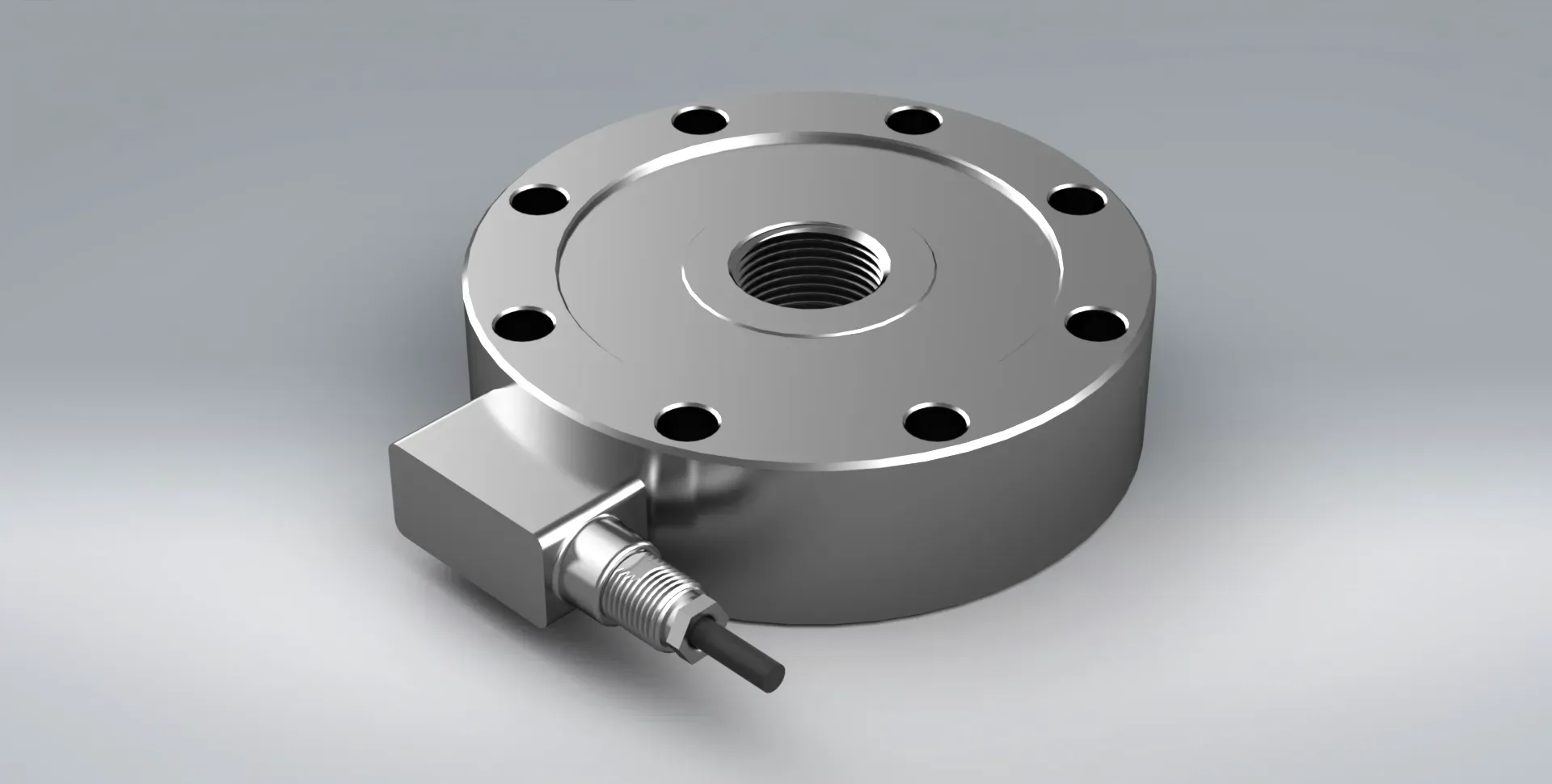

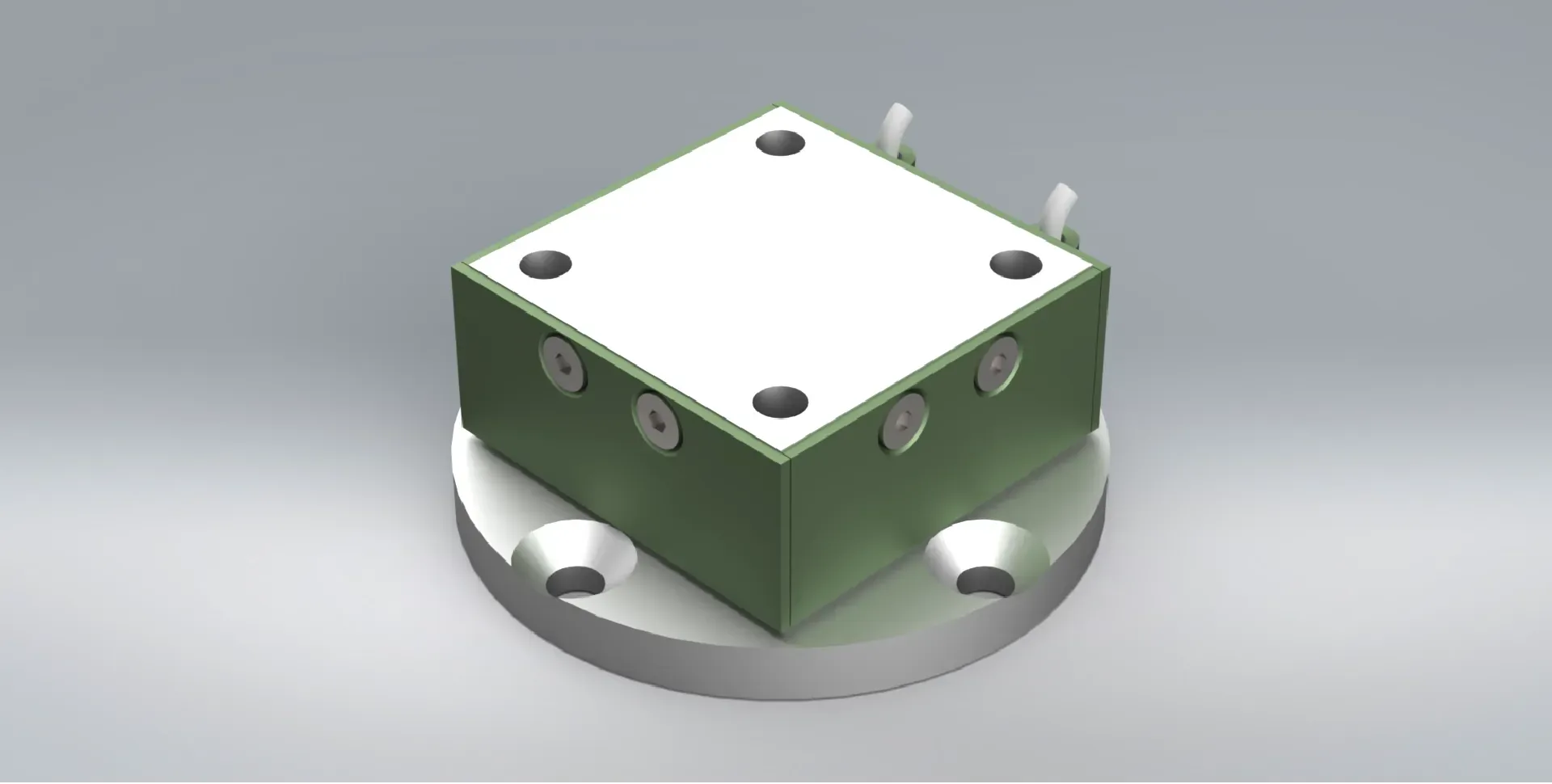

Repair Types

So long as you haven’t overloaded your device to the extent where permanent distortion of the spring element has occurred, we can restore its performance back to what it once was when purchased new, by using techniques identical to those used in the manufacture of our own transducers.

Poorly manufactured transducers will eventually fail in fatigue if the solder joints within them are too massy. In such cases, we will re-wire the item following best practises, taking care to minimize the profile of all solder joints.

Inadequate surface preparation or incorrect adhesive cure conditions during manufacture give rise to poor bonds that will unexpectedly fail under load, allowing gauge delamination to occur. Alternatively, overloading a transducer such that the elongation capability of a strain gauge grid is exceeded, will cause the grid to fracture. In either case, the spring element will need to be re-gauged and re-wired to achieve normal functioning of the component once more.